Technology

How Do You Know if You Need Custom Machining?

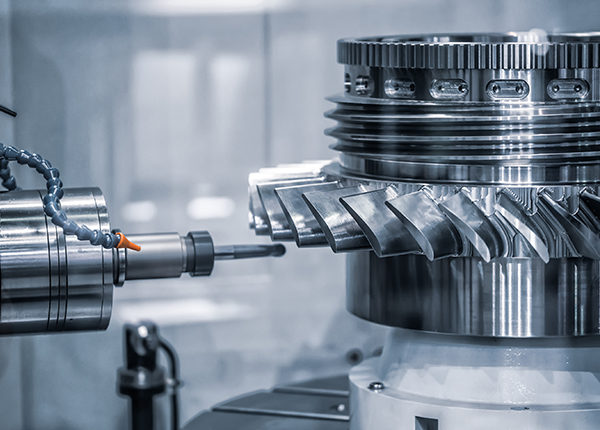

Machining is often the fastest way to get parts that manufacturers need. Today’s technology and online catalogs make this process even faster and easier. When you choose your parts from a catalog, they are generally made with standard CNC machining processes and work just fine. That being said, custom machining is another option that can enhance your production in certain situations.

What It Is

It involves standard machining practices at their most basic form to create parts that do not exist in a catalog. These parts are created specifically to meet a manufacturer’s needs. For instance, it is often used for novelty designs that require parts that you cannot purchase from the standard marketplace.

The components that can be made using this process can be any size imaginable. They can also be made with unique features, such as engraving. This is also an option if you are looking for a prototype that makes a design more efficient by combining several parts. Since they are custom ordered, they can be completely tailored by the client with a specific end-use in mind, rather than a general audience.

When It Is Great

There are several times when a business would consider having parts custom-made. These include when a part is not available elsewhere, nonstandard parts are necessary, multiple parts are being combined for efficiency, high-quality parts are necessary for an emergency, small quantities of a rare part are required.

The Various Types

Because there are so many parts that can be made through this process, there are many types, from hand milling to high-end machines, working on everything from new plastics to traditional metals. The type that is used is often based on the size and specifications of the part being made. For instance, certain parts must be made by hand with one tool, while others can be manufactured using several machines.

When You Can Use an Alternative

While getting your parts custom-made is a great option many times, there are some times when ordering traditionally machined parts is the best fit. There are also other alternatives for various materials, such as injection molding for plastics. These options are generally the best when custom-made parts are not something that fits into your company’s budget.

In short, there are some qualities of getting your parts custom-made that appeal to businesses. While this is a great option if you need to meet tight tolerances or have specialty parts, it is not always the answer.